Key Summary:

- Proper installation of an electric chain hoist ensures safety, efficiency, and long equipment life.

- Preparation, alignment, and adherence to OSHA, ASME, and HMI standards are critical for compliance.

- Installation includes mounting, wiring, safety testing, and load certification before use.

- Crane 1 provides expert hoist installation, inspection, and ongoing maintenance across all major brands.

Why Proper Installation Matters

An electric chain hoist is a powerful piece of lifting equipment, but improper installation can create safety hazards, cause damage, and reduce performance. Following OSHA, ASME, and HMI guidelines ensures the hoist operates safely and efficiently. These standards cover everything from load testing to electrical safety, guaranteeing a reliable and compliant setup for your operation.

Step 1: Prepare the Installation Site

Before installing your electric chain hoist, confirm that the supporting structure can handle the hoist’s rated capacity and dynamic loads. The area should be clear, level, and free of structural defects. Check headroom, hook travel, and operating space to ensure safe and smooth operation.

- Verify the load-bearing capacity of beams or trolleys.

- Confirm the mounting type (hook, lug, or trolley).

- Inspect fasteners and brackets for damage or corrosion.

Step 2: Mount the Hoist

Mounting the hoist properly is critical to avoid side loading or uneven stress. Align the hoist directly beneath the load path, ensuring all bolts and attachments meet manufacturer torque requirements. If installed as part of an overhead crane system, verify that the runway and beam alignment meet design tolerances.

- Fit trolley wheels securely to the beam flange.

- Center the hoist under the intended load line.

- Confirm that movement is smooth and free of binding.

Step 3: Connect Electrical Power

Follow the manufacturer’s wiring diagram and match the hoist’s power rating to your facility’s voltage, phase, and frequency. All electrical work must comply with OSHA electrical safety regulations and the National Electrical Code (NEC). Proper grounding and circuit protection are essential for operator safety.

- Install a disconnect switch and emergency stop near the operator station.

- Use appropriately rated cables and connectors.

- Verify motor rotation direction before use.

Step 4: Test Controls and Safety Devices

Before lifting a load, test all controls and safety mechanisms. The up/down controls must respond accurately, limit switches should engage properly, and brakes must hold securely. Safety testing ensures compliance with ASME B30.16 and HMI standards for hoist operation.

- Test pendant or remote controls.

- Verify upper and lower limit switch operation.

- Ensure emergency stop and braking systems work as intended.

Step 5: Perform a Load Test

After confirming all mechanical and electrical systems are functioning correctly, conduct a rated load test per ASME B30.16 and HMI specifications. This verifies that the hoist can safely lift and hold its rated capacity. Record test data for OSHA and internal documentation.

Step 6: Train Operators and Schedule Maintenance

Operator training is required by OSHA 1910.179 and ASME B30.16. Training ensures personnel understand proper use, emergency procedures, and inspection requirements. Preventive maintenance – including regular lubrication, chain inspection, and control testing – keeps your hoist safe and reliable. Crane 1 offers operator training and scheduled maintenance programs for long-term performance and compliance.

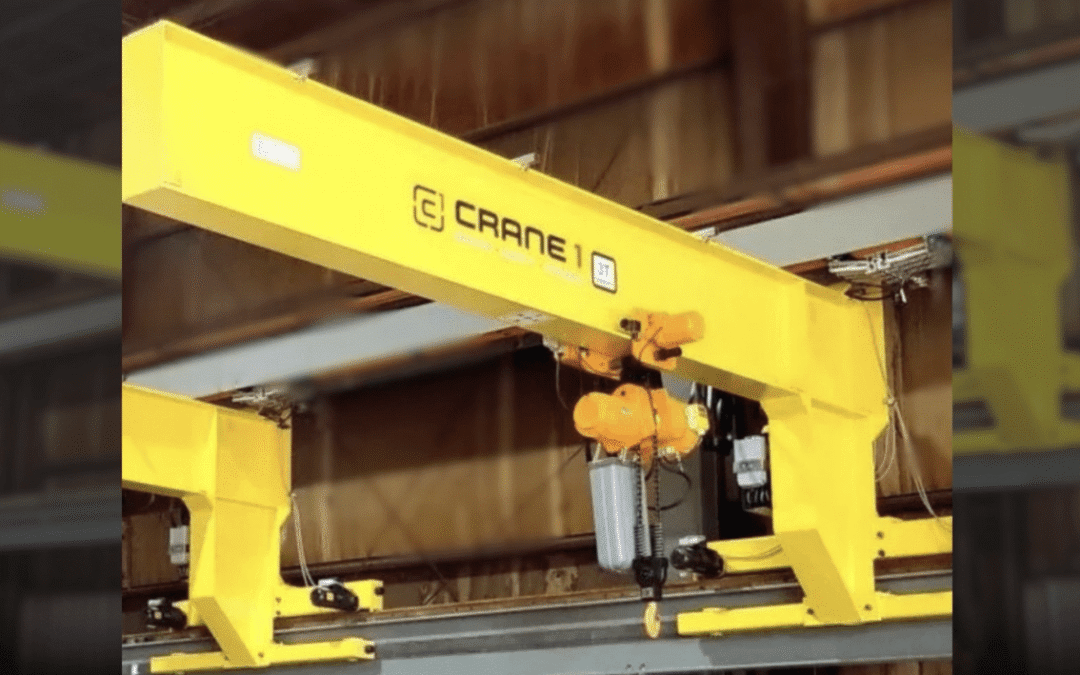

Professional Hoist Installation Services

Installing an electric chain hoist requires precision and regulatory expertise. At Crane 1, we install and service electric chain hoists from all major manufacturers, including Harrington, Columbus McKinnon, R&M, and Demag. Our technicians ensure every system is installed, tested, and documented according to OSHA, ASME, and HMI standards. Contact us today to schedule a professional installation or consultation.

Frequently Asked Questions

Can I install an electric chain hoist myself?

Small-capacity hoists can sometimes be installed in-house, but industrial models should always be installed by trained technicians to meet OSHA, ASME, and HMI compliance.

Do electric chain hoists need certification after installation?

Yes. A rated load test and inspection in accordance with ASME B30.16 and HMI requirements must be completed before the hoist is put into service.

What’s the difference between a hook-mounted and trolley-mounted hoist?

Hook-mounted hoists are stationary, while trolley-mounted hoists travel along a beam or crane runway for greater reach and flexibility.

How often should a hoist be inspected after installation?

OSHA mandates frequent visual inspections and periodic comprehensive inspections by qualified personnel. Regular inspections prevent wear-related failures and maintain compliance.

What industries rely most on electric chain hoists?

Electric chain hoists are used in manufacturing, automotive, aerospace, energy, and logistics industries to ensure efficient and safe material handling.